Date:

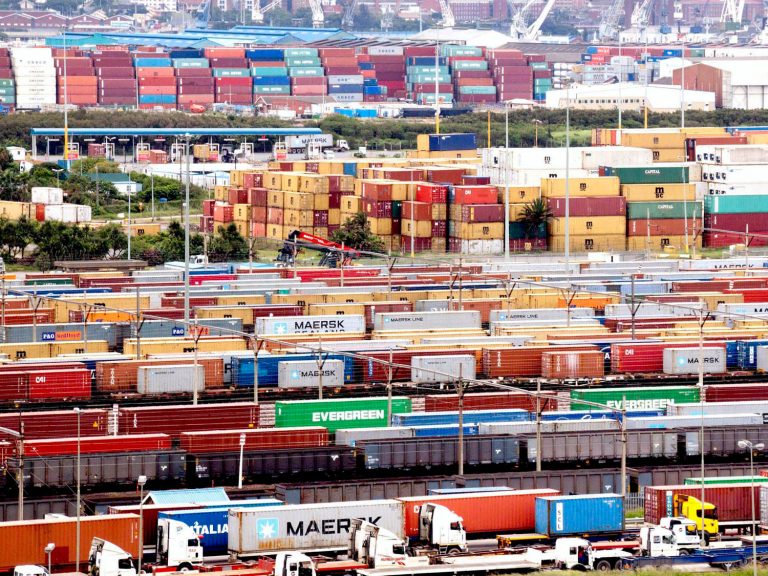

Coronavirus highlights need for visibility

The Coronavirus pandemic has illustrated, like no prior crisis, the critical need of end to end visibility for supply chain agility, risk management and contingency planning.

While business may endeavour to provide the highest quality (or at least optimum) products at the lowest cost, their global supply chains are often a ‘build it and, if it ain’t broke, leave it’ production line.

As the Coronavirus pandemic has highlighted right from the start, the notion that a detailed supplier identification, verification and qualification process will not require frequent revisits, to review and validate past decisions is at best naive. At worst, is damaging to business.

“Metro’s cloud-based, hyper-secure MVT system manages global operations and complex global supply chains; from supplier to carriers, distribution networks and customers, provide complete real-time visibility, control and intelligence.”

International sourcing

Companies initially plan their extended supply chains when pursuing an international sourcing initiative, but this should be revisited on a regular basis to ensure that the chosen supply chain continues to meet the companies’ needs.

The lowest total cost of supply is the objective, yet as manufacturing declined in Western economies, the only primary source for production was China.

In recent years other supply sourcing regions have become more attractive including India, Malaysia and Thailand, and closer to home Turkey, Eastern Europe and Africa. The UK has also seen strong manufacturing output increases over the last 5 years.

The cost of labour and raw material fluctuates in all these countries, with an overall upwards trajectory that varies country to country.

More frequent price instability in local markets, together with tariff and preference uncertainties should increase regularity of supply chain reviews of the global supply chain to ensure effectiveness and that strategic objectives are still being fulfilled.

Complexity

It is undoubtedly easier for the supply chain team to manage a single production site, within a single manufacturer, in a single country, but if that country is subject to a sudden tariff spike (let alone an actual crisis), the supply chain team (and the business) will quickly find itself with no choice but to accept increase in costs, margin reduction and.more than likely, falling service levels.

Simplicity, is not the right choice.

Businesses of all sizes are complex. From managing finances and HR, to ensuring regulatory and legal compliance, managers and directors constantly navigate their way through an endless stream of processes and procedures daily.

It adds complexity, but moving to multi-country/multi-supplier sourcing provides opportunities to compare and contrast performance and cost indicators and with it, the option to switch volumes between suppliers/countries to mitigate the impact of tariff spikes (or crises) or as performance dictates, to achieve:

- Higher service levels

- Reduced stock-outs

- Lower cost supply

- More efficient inventory management

- Lower transportation costs

- Higher gross margins

- Increased top-line sales

Visibility

Supply chains compete in complex and rapidly changing business environments and supply chain agility and resilience have become critical capabilities.

To increase agility and resilience, supply chain managers need to understand the global reality of their supply chain. A moving snapshot, in real-time.

Accurate real-time data, that provides greater visibility into stakeholder actions/inactions and factors affecting end-to-end supply chain performance.

Managers often claim, however, that they are awash in data yet lacking in valuable information.

Taken together, these conditions suggest that supply chain visibility is a necessary, but insufficient capability for many seeking supply chain agility and resilience.

Metro’s cloud-based, hyper-secure MVT system manages global operations and complex global supply chains; from supplier to carriers, distribution networks and customers, providing complete real-time visibility, control and intelligence.

MVT’s modular platforms are configurable to individual customer needs and situation, consolidating multiple data sources, to deliver unparalleled visibility, insight and control, with data-driven decision making.

Please contact Metro for a demonstration on how our MVT systems can be tailored to assist in the management’s visibility and control of your logistics platforms.